As an expert in the toy industry, I have seen firsthand the complex and fascinating process of creating toys in a factory. From the initial design stages to the final product on store shelves, there are numerous steps and considerations that go into making a successful toy. In this article, I will take you through the 65 main steps involved in toy manufacturing and shed light on the behind-the-scenes work that goes into creating your favorite toys.

The Beginning Stages: Design and Concept

The first step in creating a toy is coming up with a concept. This involves understanding the customer's goals, characters, fans, and overall universe.As a manufacturer, we take the time to learn about our clients and their vision for their toys. This allows us to create custom concepts that align with their objectives and challenges. Once we have a solid understanding of the concept, we combine our expertise in design and manufacturing to come up with recommendations for the toy. We also consider packaging ideas and all aspects of the final product at this stage.

Prototyping and Production

After the concept has been approved, we move on to prototyping. This involves using a combination of 3D modeling, rapid prototyping, hand sculpting, molding, and casting to create a physical model of the toy.Once this model is approved, we move on to creating painted prototypes and designing packaging. Once all aspects of the toy have been finalized, it is sent to the manufacturer for mass production. One of the most common methods used in toy manufacturing is injection molding, where plastic is injected into a mold to form different parts of the toy.

The Importance of Quality Control

Before a toy hits store shelves, it goes through rigorous testing to ensure its durability and longevity. This includes testing for durability during transit and arrival at stores. We also pay close attention to the craftsmanship of each toy, from the smallest details like bulging veins on a Hulk action figure to the overall quality of the plastic used.The Role of Intellectual Property

In the toy industry, intellectual property is a crucial aspect that must be considered.Companies must secure the rights to manufacture toys based on popular characters or franchises. This can involve obtaining patents and navigating the technicalities involved in the process.

Finding the Right Manufacturer

For independent toy manufacturers, finding the right factory to produce their toys is essential. This involves considering factors such as packaging, quality, and cost estimates. The Toy Association offers resources to help navigate this process, and attending events like the annual International Toy Fair in New York can also provide valuable insights.The Art of Toy Making

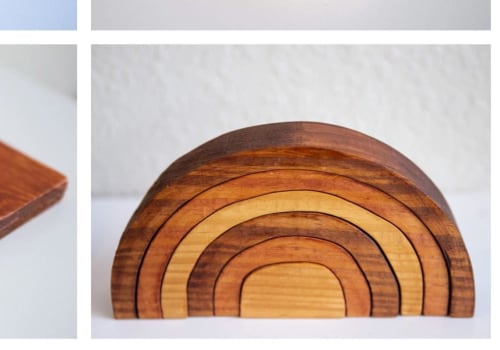

While the process of toy manufacturing may seem technical and mechanical, there is an artistry involved in creating each toy.From hand sculpting to intricate design work, every step requires skill and precision. It's important not to overlook this aspect of toy making, as it is what brings each toy to life.

The Final Product

After months of hard work and dedication, the final product is ready to hit store shelves. As a manufacturer, our ultimate goal is to bring happiness and excitement to fans through our toys. We take pride in our work and strive to make each new toy better than the last. So next time you pick up your favorite action figure or collectible, take a moment to appreciate the intricate process that went into creating it.From concept to production, there are countless steps and considerations involved in making a successful toy. And as an expert in the industry, I can confidently say that we are always working passionately to make every new toy the best ever.